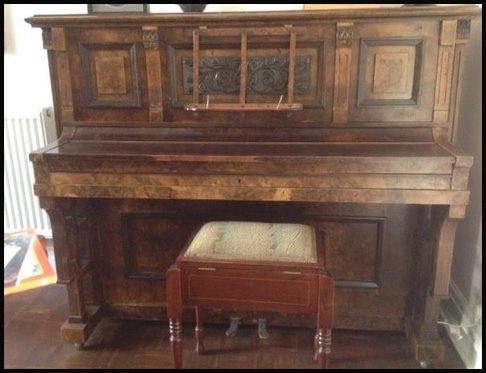

J&J Hopkinson upright piano, ARTS & CRAFTS 1907

RESTORATION PROJECT 2

"SYSTEM HOPKINSON" MODEL

**THIS PIANO IS sold**

0791 485 4072

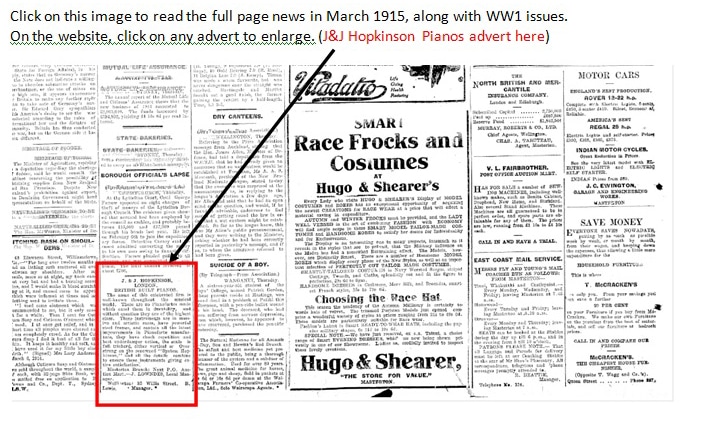

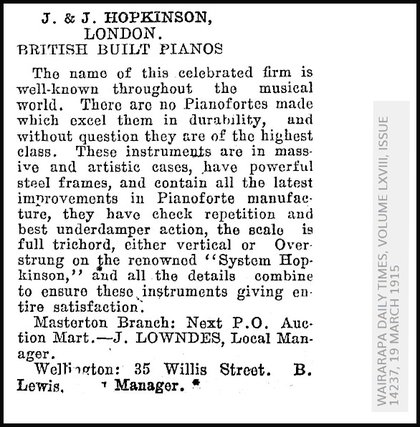

J&J HOPKINSON ARCHIVES FROM 1915

The "System" Hopkinson was the equivalent for

"Hi-tech" back in the early 1900s, and using all technological advances in their pianos & mechanisms, which are still used to this day.

Throughout this project, I will highlight all these 'system' combinations, and reflect on this advert written over one hundred years ago.

Battling through two world wars, and with conflict issues back in 1915 during WW1 (see ad below), just proved that J&J Hopkinson pianos excelled in all musical instrument developments, and travelling the world, including New Zealand.

I think we ought to be very proud of this British - built piano, and it's

no wonder we won the war!

Please click on any image to enlarge

"Hi-tech" back in the early 1900s, and using all technological advances in their pianos & mechanisms, which are still used to this day.

Throughout this project, I will highlight all these 'system' combinations, and reflect on this advert written over one hundred years ago.

Battling through two world wars, and with conflict issues back in 1915 during WW1 (see ad below), just proved that J&J Hopkinson pianos excelled in all musical instrument developments, and travelling the world, including New Zealand.

I think we ought to be very proud of this British - built piano, and it's

no wonder we won the war!

Please click on any image to enlarge

BRIEF HISTORY OF HOPKINSON

Established in 1835, John Hopkinson started his career as a music publisher in Leeds, West Yorkshire.

A year later, his brother James became a partner, and they eventually moved to London.

The company was renamed "J&J Hopkinson" (John & James).

Hopkinson opened several music shops and piano manufacturing plants throughout London including branches on

Oxford Street, Regent Street and New Bond Street; later production plant moved to Paxton Piano Works in 1963.

Earlier pianos were made by George Rogers & Sons, then taken over by Bentley (London) in the mid 1990s.

Later owned by Whelpdale, Maxwell & Codd, their estimated piano numbers in the UK alone reached over 200,000, on average,

95% of upright pianos and 5% of grand pianos still exist today. Their pianos are known world wide.

Winning many awards for excellence, their pianos are said to be....

"A very common British make, varying from very good to excellent; these pianos have a very rich and pleasing tone,

with a responsive touch."

Established in 1835, John Hopkinson started his career as a music publisher in Leeds, West Yorkshire.

A year later, his brother James became a partner, and they eventually moved to London.

The company was renamed "J&J Hopkinson" (John & James).

Hopkinson opened several music shops and piano manufacturing plants throughout London including branches on

Oxford Street, Regent Street and New Bond Street; later production plant moved to Paxton Piano Works in 1963.

Earlier pianos were made by George Rogers & Sons, then taken over by Bentley (London) in the mid 1990s.

Later owned by Whelpdale, Maxwell & Codd, their estimated piano numbers in the UK alone reached over 200,000, on average,

95% of upright pianos and 5% of grand pianos still exist today. Their pianos are known world wide.

Winning many awards for excellence, their pianos are said to be....

"A very common British make, varying from very good to excellent; these pianos have a very rich and pleasing tone,

with a responsive touch."

J&J HOPKINSON LONDON UPRIGHT PIANOFORTE

STATISTICS

STATISTICS

Serial Number: #60998 (registered with Pierce Piano Atlas, New Mexico, USA)

Year of manufacture: 1907

Cabinet: Dark Walnut / Shadow Faux / Arts & Crafts

Dimensions: Height 49' (125cm) Width 58' (147cm) Depth 26' (66cm)

Mechanism: No. 277 -- 202738 Schwander under-damped tape & jack spring action

Alloy support brackets with ball & socket feet

Stringing: Overstrung with 26 bass notes / 4 bass tenor and 55 treble / treble loop stringing system

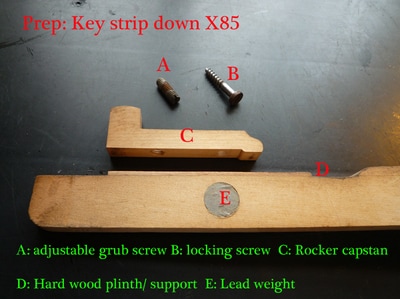

Keyboard: Original ivory & ebony / 7 octaves / 85 notes. Rear rocker capstan with grub + locking screw design

Structure: Full cast iron frame with partially exposed maple wrest plank / maple bridges / spruce soundboard

Pedals: Left 'soft' pedal (half-blow rail) and Right sustain pedal / leaf spring return/brass caps on wrought iron

Hammers: 85 Schwander hammers with butt return springs.

Undercarriages: 85 Schwander levers & jacks with back checks / spiral jack return springs

Dampers: 66 Schwander dampers / 12 single clip / 18 bi-chord wedge / 36 stitched/ flat felt - all red backed

CABINET DETAILS

Year of manufacture: 1907

Cabinet: Dark Walnut / Shadow Faux / Arts & Crafts

Dimensions: Height 49' (125cm) Width 58' (147cm) Depth 26' (66cm)

Mechanism: No. 277 -- 202738 Schwander under-damped tape & jack spring action

Alloy support brackets with ball & socket feet

Stringing: Overstrung with 26 bass notes / 4 bass tenor and 55 treble / treble loop stringing system

Keyboard: Original ivory & ebony / 7 octaves / 85 notes. Rear rocker capstan with grub + locking screw design

Structure: Full cast iron frame with partially exposed maple wrest plank / maple bridges / spruce soundboard

Pedals: Left 'soft' pedal (half-blow rail) and Right sustain pedal / leaf spring return/brass caps on wrought iron

Hammers: 85 Schwander hammers with butt return springs.

Undercarriages: 85 Schwander levers & jacks with back checks / spiral jack return springs

Dampers: 66 Schwander dampers / 12 single clip / 18 bi-chord wedge / 36 stitched/ flat felt - all red backed

CABINET DETAILS

ARTS & CRAFTS PERIOD

FRONT PANEL WITH CENTRE PIECE CARVING OF FOLIAGE

INCLUDING FLOWER BUDS, LEAVES, STEMS & SCROLLS

CONCERTINA-STYLE FOLD OUT MUSIC REST

VERTICAL TRUSS COLUMNS WITH CARVED ORNAMENTATION

PROTRUDING OUTER VERTICAL COLUMNS

IN - TURNED & SQUARE ENDED CHEEKS WITH FRONT FOLDING FALLBOARD (Broadwood style)

TOP LID WITH PERIOD TAPERED MOULD TRIMS / MITRED CORNERS

ROBUST VERTICAL DUAL 'GATE' LEGS

IN - TURNED FRONT WITH STALACTITE DESIGN

LOWER PANEL - LARGE RECTANGULAR INNER PANEL

WITH MOULD TRIMS

CABINET ASSESSMENT

Cabinet in reasonably good condition for age, with minor defects / small scratches / some veneer edges require attention.

French polish generally "flat" in places and requires reviving / few faded areas

Top lid RH rear trim replaced, and both brass sconces missing from front panel.

Sconce panels will be removed / stripped / holes filled in and re-polished to match (sconces not to be replaced)

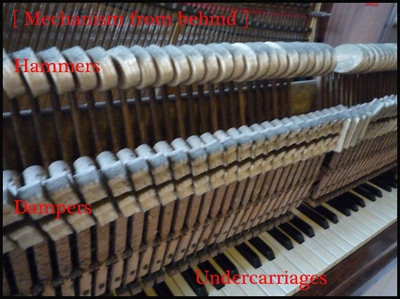

MECHANISM ASSESSMENT

The piano was very difficult to play, and multiple intermittent problems. Notes would play once only, but upon repetition of the same note, the note would not work. This is a combination of seized & slow returning hammers, undercarriages & jacks. Most of the dampers worked, but delayed in muting the strings because they partly rely on the undercarriage's damper spoon to return the dampers.

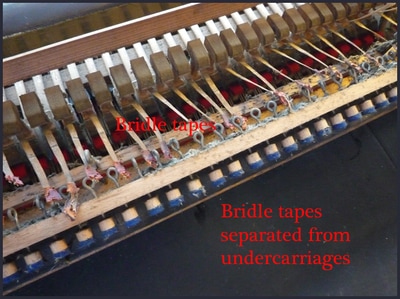

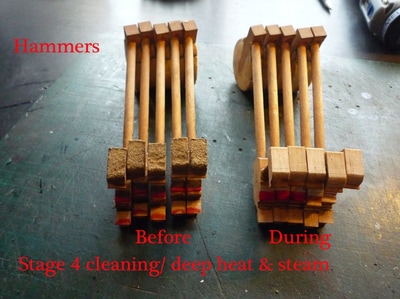

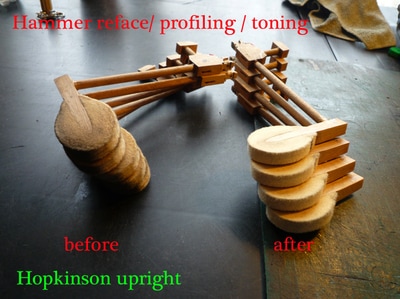

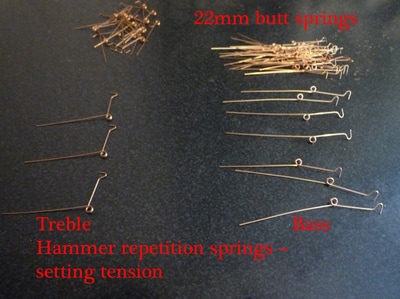

Hammer head felts in average condition, with black soot deposits (possibly from open fires); some treble hammer felts badly scuffed due to previous DIY string repairs. About 95% of the hammer butt (return) springs were missing their hooks and broken off from the flange loops. The remaining springs broke into several pieces when stripped down. All bridle tapes, leathers and loops perished and worn away. All hammers to be completely stripped/ re-pinned and rebuilt with new parts / hammer head felts to be re-faced & toned.

The mechanism rails (e.g. top of damper flange rail), left thick deposits of mildew and dust / formed into a carpet.

This has been cleared away, and there are no wooden fractures or cracked parts.

Undercarriages: About 60% of the lever flanges are seized and require re-pinning. Jack springs to be tensioned. Back check felt in good condition. Bridle and check wires to be burnished. All undercarriages and jacks will be fully restored.

Dampers: Thick black deposits on all LH facing felts and worn. When removed, the springs lose contact with the damper levers, and need replacing. Damper flanges in good condition for age, and has the preferred spring key leaning on the damper wall, instead of the damper spring wires threaded through a hole in each flange. Rear cream box cloth worn. Dampers to be fully restored.

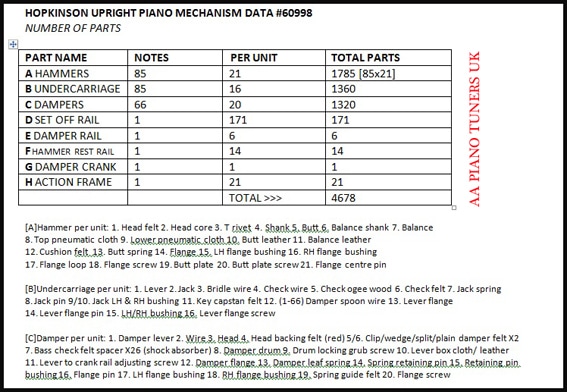

Parts have been recorded as accurately as possible, but may vary.

When I show a part of the restoration, I may refer to the "unit" numbers above

Example: "Hammer head re-facing & cleaning A1/ A3"

<1> PREPARATION/ PRE - REGULATION

Before any parts are removed and dismantled, certain measurements are calculated and distances of travelling parts are recorded for the final stages of installation (in about 3-4 months time); using various jigs, measuring rule and vernier calipers, all major parts are carefully measured such as key dip, ivory key height and hammer distance to string.... this is called "pre-regulation". During the final stages of installation (just before tuning), all parts are then "regulated" and adjusted for optimum mechanical movement and timing.

Here are some internal photos taken before removal of parts with notes >>

Before any parts are removed and dismantled, certain measurements are calculated and distances of travelling parts are recorded for the final stages of installation (in about 3-4 months time); using various jigs, measuring rule and vernier calipers, all major parts are carefully measured such as key dip, ivory key height and hammer distance to string.... this is called "pre-regulation". During the final stages of installation (just before tuning), all parts are then "regulated" and adjusted for optimum mechanical movement and timing.

Here are some internal photos taken before removal of parts with notes >>

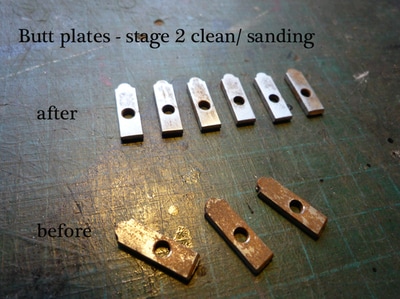

<2> CLEANING

A piano over 100 years of age carries about half a shopping bag's worth of dust, debris and foreign objects.

Where anything is more or less horizontal + flat (key frame under keys, action rails) thick dust accumulates.

My cleaning process is very thorough, and there is up to four stages of cleaning before any new part is added.

Stage 1 cleaning: Mechanism bellow out / vacuum clean with small nozzle (done outside)

Stage 2 cleaning: Pre-clean parts as removed & numbered in pencil one by one with a dry paint brush/ removing side dust

Stage 3 cleaning: All wooden parts cleaned and wiped with a damp cloth, re-numbered in black pen

Stage 4 cleaning: Deep clean with medium hot iron and hot damp/wet cloth for removal of glue/ impregnated materials

There are different cleaning procedures for certain parts, which must be carried out dry, such as hammer head felts, and the burnishing and polishing of ivories. Any internal mechanism parts made of metal (e.g. hammer butt plates and screws/ bridle wires) undergo a separate cleaning process to remove rust by sanding/ wire wool, methylated spirits clean, then spray or brush painted to protect the metal. Most metal components in a piano mechanism are not protected with any kind of lacquer or coating - just the raw steel parts.... so I ensure all metal parts are upgraded and fully protected against rust and corrosion - this also applies to brassware such as the pedals.

A piano over 100 years of age carries about half a shopping bag's worth of dust, debris and foreign objects.

Where anything is more or less horizontal + flat (key frame under keys, action rails) thick dust accumulates.

My cleaning process is very thorough, and there is up to four stages of cleaning before any new part is added.

Stage 1 cleaning: Mechanism bellow out / vacuum clean with small nozzle (done outside)

Stage 2 cleaning: Pre-clean parts as removed & numbered in pencil one by one with a dry paint brush/ removing side dust

Stage 3 cleaning: All wooden parts cleaned and wiped with a damp cloth, re-numbered in black pen

Stage 4 cleaning: Deep clean with medium hot iron and hot damp/wet cloth for removal of glue/ impregnated materials

There are different cleaning procedures for certain parts, which must be carried out dry, such as hammer head felts, and the burnishing and polishing of ivories. Any internal mechanism parts made of metal (e.g. hammer butt plates and screws/ bridle wires) undergo a separate cleaning process to remove rust by sanding/ wire wool, methylated spirits clean, then spray or brush painted to protect the metal. Most metal components in a piano mechanism are not protected with any kind of lacquer or coating - just the raw steel parts.... so I ensure all metal parts are upgraded and fully protected against rust and corrosion - this also applies to brassware such as the pedals.

DISMANTLE / STRIPDOWN / CLEANING

Including further measurements, keyboard and hammer removal >>

Including further measurements, keyboard and hammer removal >>

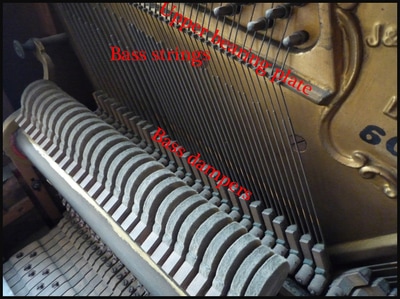

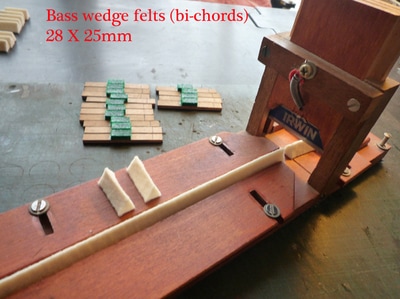

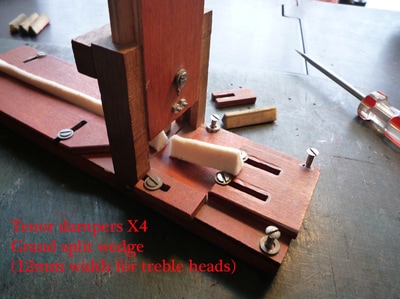

<3> PREPARATION: DAMPERS X 66

The dampers are responsible for stopping the sound after letting go of a note (hence 'dampen'), and they are grouped into sections with different shaped felts, depending on the strings they are muting. Working from left to right, the bass dampers are stripped down, then tenor, then treble. The dampers also control the level of "sustain" and legato and connected to the sustain pedal.

Few images of the bass & tenor dampers during strip down >>> .

The dampers are responsible for stopping the sound after letting go of a note (hence 'dampen'), and they are grouped into sections with different shaped felts, depending on the strings they are muting. Working from left to right, the bass dampers are stripped down, then tenor, then treble. The dampers also control the level of "sustain" and legato and connected to the sustain pedal.

Few images of the bass & tenor dampers during strip down >>> .

INTERMEDIATE PREPARATION

Whilst waiting for new piano materials and parts to arrive, other areas of the restoration prep stages are started.

Rarely are parts restored from start to finish in one go - I prefer to vary the workload.

This includes things like tool prep / fitting new cutting blades / cleaning / new toning needles for hammers etc.

<4> KEYBOARD PREP

All 85 piano keys have wooden rocker capstans - this is a German design fitted to a UK piano.

During the last stages of regulation, the adjustable grub screws (A) must not be seized and free for adjustment when installed back onto the key frame. This is an ideal time to start this work.

An overview of the work is assessed: Ivory condition & joins / grub screw seizures (rust) / grub screw slots / bushing cloth/ bent screws

Whilst waiting for new piano materials and parts to arrive, other areas of the restoration prep stages are started.

Rarely are parts restored from start to finish in one go - I prefer to vary the workload.

This includes things like tool prep / fitting new cutting blades / cleaning / new toning needles for hammers etc.

<4> KEYBOARD PREP

All 85 piano keys have wooden rocker capstans - this is a German design fitted to a UK piano.

During the last stages of regulation, the adjustable grub screws (A) must not be seized and free for adjustment when installed back onto the key frame. This is an ideal time to start this work.

An overview of the work is assessed: Ivory condition & joins / grub screw seizures (rust) / grub screw slots / bushing cloth/ bent screws

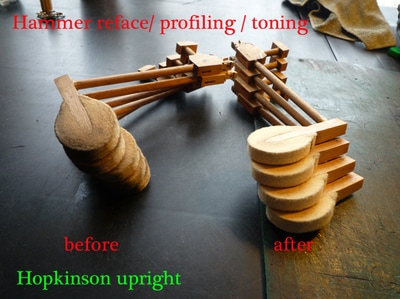

<5> HAMMER PREP: TONING TOOLS / REFACING / PROFILING HEADS

Some prep work is done before the hammers are rebuilt (while stripped down); this makes it easier to clamp the hammers, and work on them in groups of 5. The original hammer head felts have successfully been revived, and now like new.

Some prep work is done before the hammers are rebuilt (while stripped down); this makes it easier to clamp the hammers, and work on them in groups of 5. The original hammer head felts have successfully been revived, and now like new.

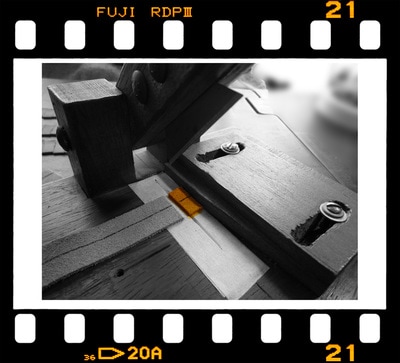

PIANO ART

Occasional highlighted images with borders will be shown at certain stages of the rebuild - not in any particular order......

Occasional highlighted images with borders will be shown at certain stages of the rebuild - not in any particular order......

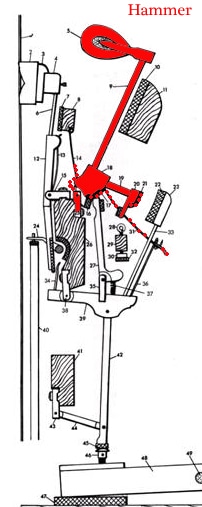

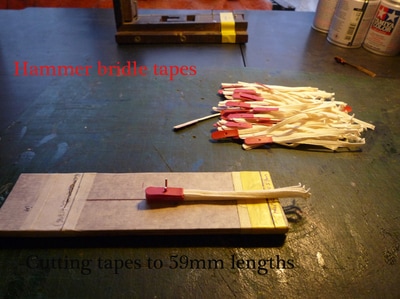

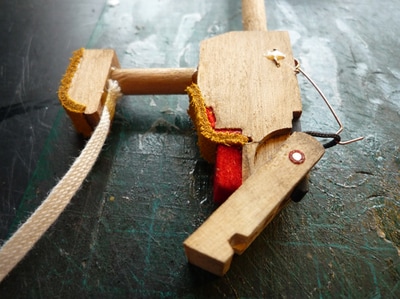

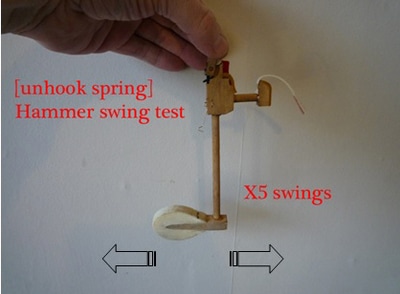

<6> HAMMER RESTORATION

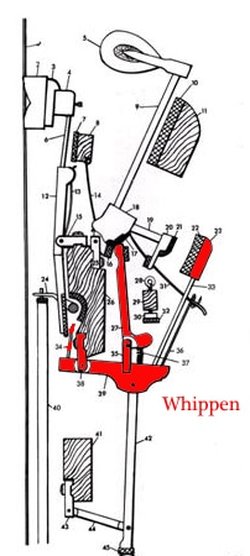

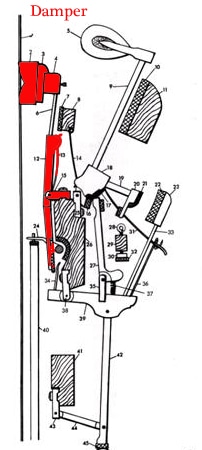

For each section of the mechanism, a diagram highlights the parts in red.

The following images show the full restoration to the hammers including; new leathers, bridle tapes, springs and more.....

For each section of the mechanism, a diagram highlights the parts in red.

The following images show the full restoration to the hammers including; new leathers, bridle tapes, springs and more.....

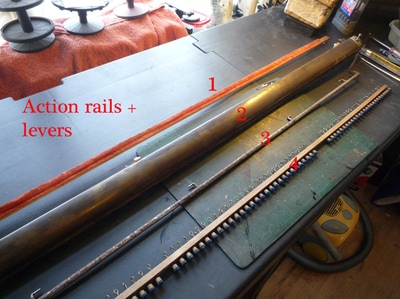

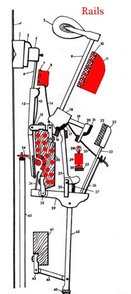

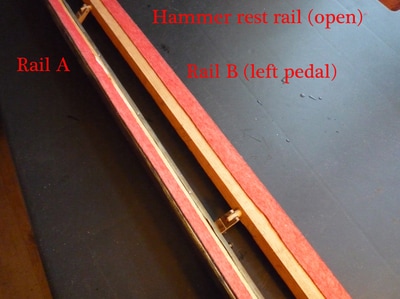

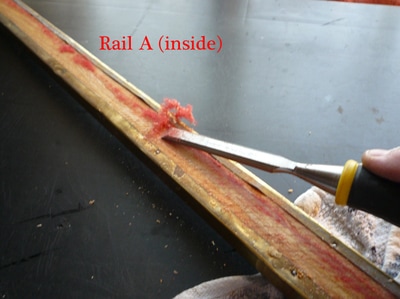

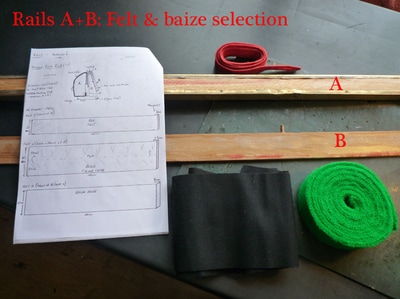

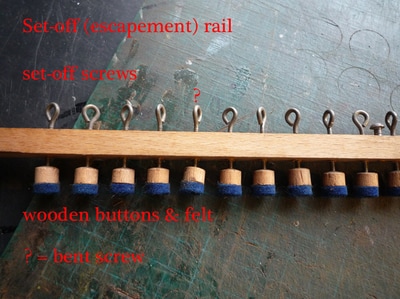

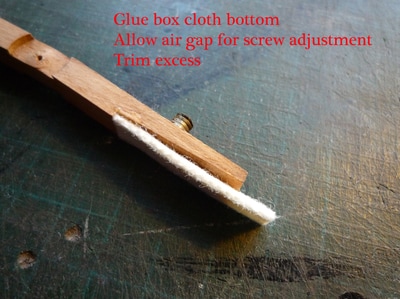

<7> ACTION RAILS

Installing a new engine and gearbox into a car with rusty mounting brackets and risky chassis is not the way forward.... so I always take just as much care and attention with all piano action rails, brackets and fixtures. A critical part of the restoration is to ensure that the hammer rest rail is fully restored with exactly the right thickness of felt and baize; this is later used as a template and benchmark to regulate and adjust the optimum performance and distance of the hammers, levers and dampers - in relation to the piano keys and strings. The colour of the felt is not important - the correct gauge/ thickness is vital for a successful installation later on.

Installing a new engine and gearbox into a car with rusty mounting brackets and risky chassis is not the way forward.... so I always take just as much care and attention with all piano action rails, brackets and fixtures. A critical part of the restoration is to ensure that the hammer rest rail is fully restored with exactly the right thickness of felt and baize; this is later used as a template and benchmark to regulate and adjust the optimum performance and distance of the hammers, levers and dampers - in relation to the piano keys and strings. The colour of the felt is not important - the correct gauge/ thickness is vital for a successful installation later on.

There are four main action rails inside a piano mechanism:-

1. Damper rail (fixed position)

2. Hammer rest rail - rear (fixed) / LH soft pedal rail front (moveable)

3. Sustain pedal damper lift rail & crank lever (moveable)

4. Set-off (escapement) rail (fixed)

Each rail plays a vital part in the correct operation of the piano.

(Rail 1 not illustrated in photos to follow)

A selection of images showing some of the work >>

1. Damper rail (fixed position)

2. Hammer rest rail - rear (fixed) / LH soft pedal rail front (moveable)

3. Sustain pedal damper lift rail & crank lever (moveable)

4. Set-off (escapement) rail (fixed)

Each rail plays a vital part in the correct operation of the piano.

(Rail 1 not illustrated in photos to follow)

A selection of images showing some of the work >>

<<< Parts 41 - 45 (articulated lever/ stickers) are not fitted to the Hopkinson mechanism.

These parts are used for very tall pianos, and some makes of German pianos.

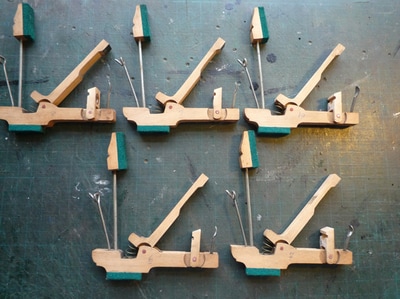

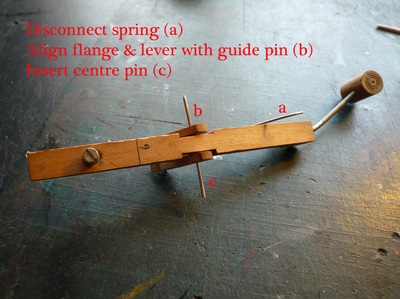

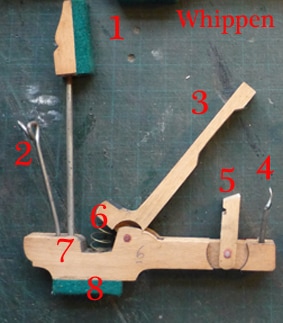

<8> WHIPPENS

The whippens are the collective names for the undercarriage levers & jacks, positioned at the lowest point of the mechanism, resting on the back of the piano keys. Often called the "levers" - these parts do various jobs such as striking the hammer forward (jack), catching the hammer on the rebound (back check), activating the dampers per note (damper spoon), and preventing the action from becoming dislocated if it is removed from the piano (bridle wire + tape).

The whippens are the collective names for the undercarriage levers & jacks, positioned at the lowest point of the mechanism, resting on the back of the piano keys. Often called the "levers" - these parts do various jobs such as striking the hammer forward (jack), catching the hammer on the rebound (back check), activating the dampers per note (damper spoon), and preventing the action from becoming dislocated if it is removed from the piano (bridle wire + tape).

Whippen parts

1. Back check

2. Bridle wire

3. Jack

4. Damper spoon

5. Flange & pin

6. Jack spring / jack toe

7. Undercarriage

8. Key capstan felt

The following images show some of the major work done >>

1. Back check

2. Bridle wire

3. Jack

4. Damper spoon

5. Flange & pin

6. Jack spring / jack toe

7. Undercarriage

8. Key capstan felt

The following images show some of the major work done >>

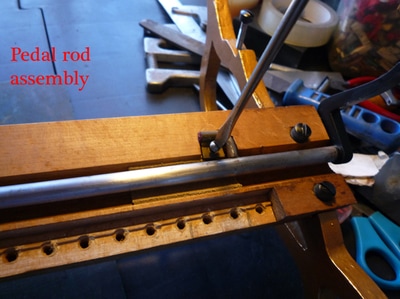

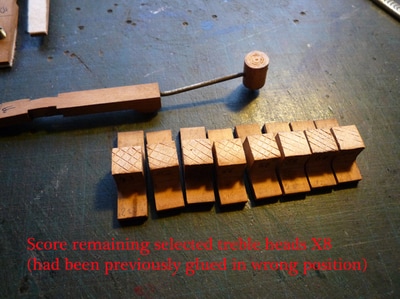

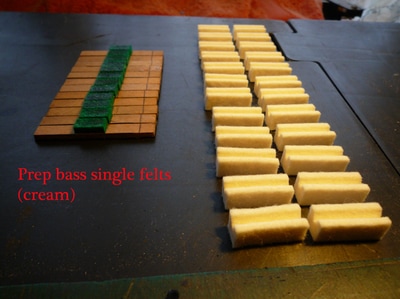

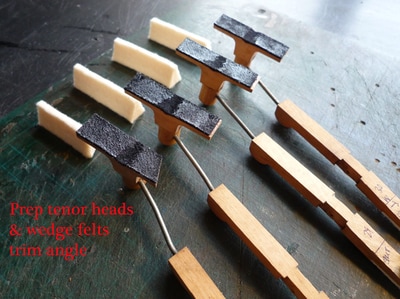

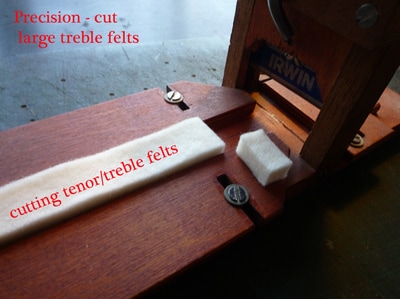

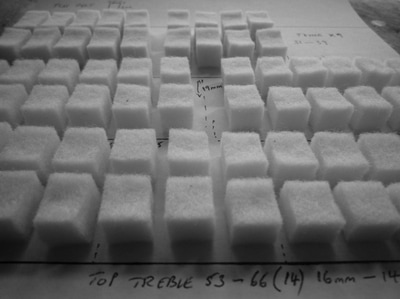

<9> DAMPERS

There are 66 dampers on the Hopkinson mechanism.

26 bass // 4 tenor // 36 treble

Although there are 85 notes in total, all pianos have dampers that only mute about two-thirds of the strings - so from notes 67 - 85, there are no dampers. The reason for this is because the shorter treble strings do not sustain for very long, and the sound quickly dies away naturally.

The dampers are located in front of and under the hammers, hence "under damped" and all modern pianos have this damper system. Each damper has a wooden head (3) and wooden drum (4) with up to two pieces of cream soft felt resting against the strings (2), and are responsible for stopping the sound after a note has been played.

Each damper is activated either "per note" by a damper spoon (34) for legato playing, or by pressing the sustain pedal, the pedal rod crank lever (24/40) lifts all the dampers simultaneously from the strings to allow more sound to sustain.

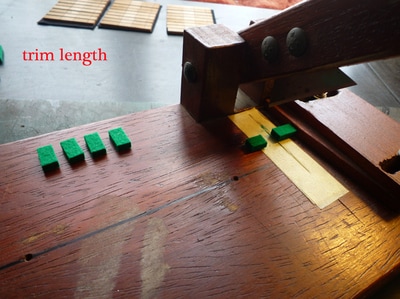

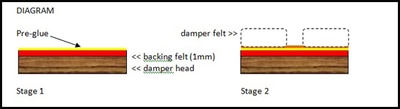

The damper system is restored in two stages:-

Stage 1: Top of damper head/ backing felt and damper felt/ lower lever "spoon" cloth

Stage 2: Damper lever (12), spring (13), flange and pin (15)

Depending on which string the damper mutes, each section of damper felt (2) is specially cut and shaped to match the profile of the string or strings. The damper springs are also graded in tension, using heavier gauge for the bass, and lighter gauge for the treble. There are three gauges of spring used.

The treble dampers are also graded in size, and gradually get smaller.

Damper restoration is a long job, taking over 50 hours

Due to their condition, they have been fully restored.

Stage 1: Showing prep work/ cloth/ backing felts/ pre-glue soaking & main damper muting felts >>

26 bass // 4 tenor // 36 treble

Although there are 85 notes in total, all pianos have dampers that only mute about two-thirds of the strings - so from notes 67 - 85, there are no dampers. The reason for this is because the shorter treble strings do not sustain for very long, and the sound quickly dies away naturally.

The dampers are located in front of and under the hammers, hence "under damped" and all modern pianos have this damper system. Each damper has a wooden head (3) and wooden drum (4) with up to two pieces of cream soft felt resting against the strings (2), and are responsible for stopping the sound after a note has been played.

Each damper is activated either "per note" by a damper spoon (34) for legato playing, or by pressing the sustain pedal, the pedal rod crank lever (24/40) lifts all the dampers simultaneously from the strings to allow more sound to sustain.

The damper system is restored in two stages:-

Stage 1: Top of damper head/ backing felt and damper felt/ lower lever "spoon" cloth

Stage 2: Damper lever (12), spring (13), flange and pin (15)

Depending on which string the damper mutes, each section of damper felt (2) is specially cut and shaped to match the profile of the string or strings. The damper springs are also graded in tension, using heavier gauge for the bass, and lighter gauge for the treble. There are three gauges of spring used.

The treble dampers are also graded in size, and gradually get smaller.

Damper restoration is a long job, taking over 50 hours

Due to their condition, they have been fully restored.

Stage 1: Showing prep work/ cloth/ backing felts/ pre-glue soaking & main damper muting felts >>

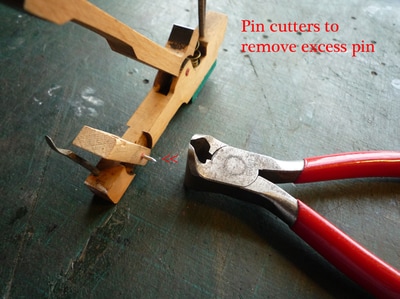

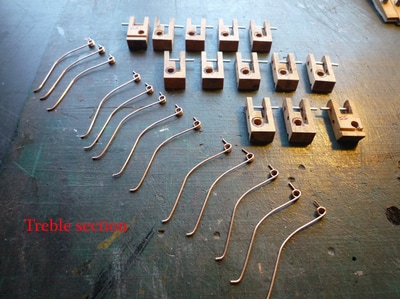

Stage 2: Damper levers, springs, flanges & pins

Each damper operates by a lever which moves backwards and forwards, either with the pedal rod or damper spoon, and attached to the mechanism rail with a square wooden flange, which is pinned to the flange as a hinge. For each damper to mute the bass strings, requires a very strong spring, tenor strings = medium strong spring, treble strings = lighter tensioned spring. There are three sets of damper springs at different gauges, and all of them are over-sized (default size) - and require shortening and re-profiling into the correct shape for the Hopkinson damper action.

The following photos show most of the damper spring/ lever & re-pin process >>

Each damper operates by a lever which moves backwards and forwards, either with the pedal rod or damper spoon, and attached to the mechanism rail with a square wooden flange, which is pinned to the flange as a hinge. For each damper to mute the bass strings, requires a very strong spring, tenor strings = medium strong spring, treble strings = lighter tensioned spring. There are three sets of damper springs at different gauges, and all of them are over-sized (default size) - and require shortening and re-profiling into the correct shape for the Hopkinson damper action.

The following photos show most of the damper spring/ lever & re-pin process >>

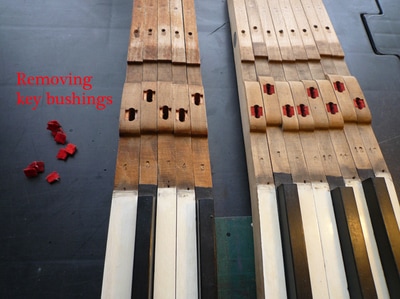

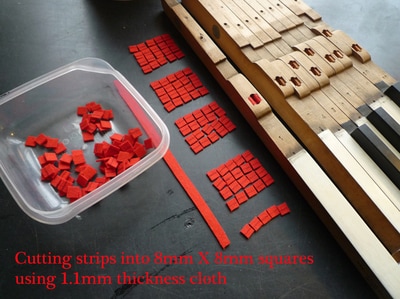

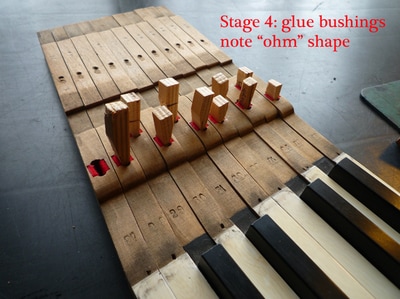

<10> KEYBOARD / CAPSTANS / IVORIES & EBONIES / BUSHINGS & KEY FRAME

(Also see section 4 for prep work)

All the piano keys have been refurbished, and working well "on the bench".

After the pedals & cabinet work, the key bed will be installed with the key frame & keys.

Here are some photos showing most of the stages >>

(Also see section 4 for prep work)

All the piano keys have been refurbished, and working well "on the bench".

After the pedals & cabinet work, the key bed will be installed with the key frame & keys.

Here are some photos showing most of the stages >>

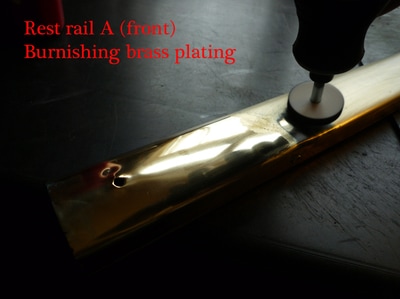

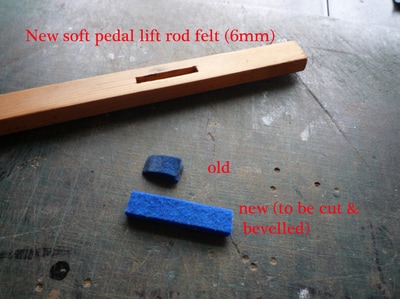

<11> PEDALS

To remove the pedals, the piano must be carefully tipped over onto its back, about 3ft in the air to gain access to the hinges.

While doing this, various cabinet parts have also been removed for small repairs & polishing.

To remove the pedals, the piano must be carefully tipped over onto its back, about 3ft in the air to gain access to the hinges.

While doing this, various cabinet parts have also been removed for small repairs & polishing.

CABINET AND MISCELLANEOUS

Some areas of the cabinet have been sensitively refurbished according to the period of the instrument, but not fully restored.

These will be pointed out to a client upon an inspection, but not every detail mentioned in an advert to sell.

Repairs include the following:-

"Feathering" and fill to some edges where veneer is chipped, marked or missing.

French polish reviver cream and bees wax applied

Areas touched up and coloured to match/ occasional fading

Sconces holes filled in to match.

TOP LID: Ebonised in satin black due to extreme poor veneer condition/ blistering / brittle veneer.

TOP RIGHT REAR TRIM: Previously replaced with quadrant/ painted dark brown/ glued back on as became loose.

Original trim moulding is unavailable/ milling and router bits obsolete.

Right side cabinet: Some shellac filler to small veneer chips/ "skirting" trim requires attention.

PIANO STOOL

A free piano stool has been provided, similar in colour to the piano, but does not match the period.

Provided as a gesture of goodwill only, and something to sit on.

Some minor work has been carried out such as: Strengthening the legs (glued and clamped); most scratches tidies up with dark brown or black boot polish. Small section of plywood glued back on (under seat); brass stay fixture area (to stool), filled with resin/ holes re-drilled and new screws fitted. RH spindle 'bead' glued as was loose. It is likely the seat cover has been replaced (green), but this has not been reupholstered. Stool may require more work as desired.

PIANO STRINGS

Two treble looped piano strings have been replaced, as were missing, using 14 gauge piano wire.

These have been pre-tuned/ stretched, and will require further tuning soon.

PITCH & TUNING

The piano is below Standard Concert Pitch, and may be a risk to pitch raise - please seek advice from your tuner.

The piano was pre-tuned in March/ new strings in treble tuned.

In the middle section, tuning pin torque is about 60% in some areas.

LOCKING KEY

An after-market key has been provided to lock the fallboard (original key missing).

A new felt pouch (blue) has been made/ pinned to store the key - inner right cabinet wall, replacing the old one.

Key escutcheon is missing.

CONCERTINA MUSIC REST

This has been refurbished along with the cabinet. Brass music clips refurbished with red felt detail for attraction.

Open the top lid to locate the music rest, which folds outwards.

IVORY KEYS

The ivory are all original, and have a slight patina yellow stain in areas, which is normal.

All the keys have been burnished & polished, then levelled. One very small crack to one ivory head (treble).

All top key bushings (red) have been replaced (section 10), and the keys eased several times.

Due to new bushings, the occasional key may "stick". or return slower than normal; please contact your piano tuner.

MECHANISM REGULATION / SERVICING

A regulation & servicing check list has been provided with this piano, outlining the areas for regulation and adjustment.

The mechanism has been regulated successfully (stage 1), however, due to new materials fitted, will require more regulation in around 2-3 months time (stage 2). For example, damper springs are brand new, and so will add additional tension to mute the strings; as the damper felt embeds itself to the strings (and damper spoon box cloth), some dampers may not lift fully, and will require further adjustment - this is perfectly normal for the mechanism to react this way - this is known as "pre regulation". Also, the key capstans may need further adjustment to compensate for compression of new hammer notch leathers (lost motion). If you feel (or hear) a note not performing quite right, it will need further adjustment. Note that mechanism regulation and servicing is separate to a piano tuning, and may require a separate visit. Please contact your piano tuner for more details.

This completes the restoration program to this piano.

Thank you for watching.

AA PIANO TUNERS UK

Some areas of the cabinet have been sensitively refurbished according to the period of the instrument, but not fully restored.

These will be pointed out to a client upon an inspection, but not every detail mentioned in an advert to sell.

Repairs include the following:-

"Feathering" and fill to some edges where veneer is chipped, marked or missing.

French polish reviver cream and bees wax applied

Areas touched up and coloured to match/ occasional fading

Sconces holes filled in to match.

TOP LID: Ebonised in satin black due to extreme poor veneer condition/ blistering / brittle veneer.

TOP RIGHT REAR TRIM: Previously replaced with quadrant/ painted dark brown/ glued back on as became loose.

Original trim moulding is unavailable/ milling and router bits obsolete.

Right side cabinet: Some shellac filler to small veneer chips/ "skirting" trim requires attention.

PIANO STOOL

A free piano stool has been provided, similar in colour to the piano, but does not match the period.

Provided as a gesture of goodwill only, and something to sit on.

Some minor work has been carried out such as: Strengthening the legs (glued and clamped); most scratches tidies up with dark brown or black boot polish. Small section of plywood glued back on (under seat); brass stay fixture area (to stool), filled with resin/ holes re-drilled and new screws fitted. RH spindle 'bead' glued as was loose. It is likely the seat cover has been replaced (green), but this has not been reupholstered. Stool may require more work as desired.

PIANO STRINGS

Two treble looped piano strings have been replaced, as were missing, using 14 gauge piano wire.

These have been pre-tuned/ stretched, and will require further tuning soon.

PITCH & TUNING

The piano is below Standard Concert Pitch, and may be a risk to pitch raise - please seek advice from your tuner.

The piano was pre-tuned in March/ new strings in treble tuned.

In the middle section, tuning pin torque is about 60% in some areas.

LOCKING KEY

An after-market key has been provided to lock the fallboard (original key missing).

A new felt pouch (blue) has been made/ pinned to store the key - inner right cabinet wall, replacing the old one.

Key escutcheon is missing.

CONCERTINA MUSIC REST

This has been refurbished along with the cabinet. Brass music clips refurbished with red felt detail for attraction.

Open the top lid to locate the music rest, which folds outwards.

IVORY KEYS

The ivory are all original, and have a slight patina yellow stain in areas, which is normal.

All the keys have been burnished & polished, then levelled. One very small crack to one ivory head (treble).

All top key bushings (red) have been replaced (section 10), and the keys eased several times.

Due to new bushings, the occasional key may "stick". or return slower than normal; please contact your piano tuner.

MECHANISM REGULATION / SERVICING

A regulation & servicing check list has been provided with this piano, outlining the areas for regulation and adjustment.

The mechanism has been regulated successfully (stage 1), however, due to new materials fitted, will require more regulation in around 2-3 months time (stage 2). For example, damper springs are brand new, and so will add additional tension to mute the strings; as the damper felt embeds itself to the strings (and damper spoon box cloth), some dampers may not lift fully, and will require further adjustment - this is perfectly normal for the mechanism to react this way - this is known as "pre regulation". Also, the key capstans may need further adjustment to compensate for compression of new hammer notch leathers (lost motion). If you feel (or hear) a note not performing quite right, it will need further adjustment. Note that mechanism regulation and servicing is separate to a piano tuning, and may require a separate visit. Please contact your piano tuner for more details.

This completes the restoration program to this piano.

Thank you for watching.

AA PIANO TUNERS UK